PRODUCTS

- Details

-

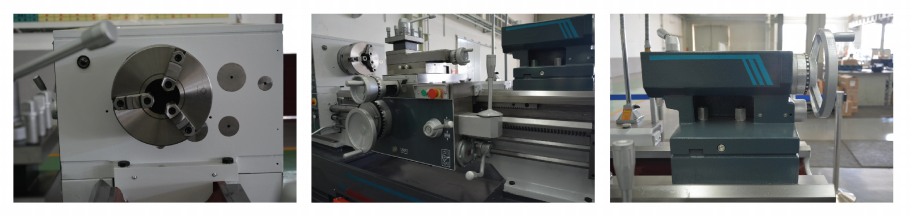

- Commodity name: CDS-B Series

- Commodity ID: CDS-B Series

▌Introduction

CDS B/C series compact laths can perform a variety of turning applications, for example: to produce internal and external cylindrical surface, end face and conical surface; Gap lathe is used to cut larger diameter or irregular shaped parts. Metric or imperial leadscrew lathe are available to produce metric, inch, module and diametral pitches upon the customer's request, and also accomplish diling, reaming and oil grooving.

▌Characteristic

◆ The lathe bed is cast with high-strength cast iron, and the lathe bed guide rails are of mountain shaped and plane guide rail layout, with Large bearing section, therefore, it has good rigidity and shock absorption, which can ensure high-precision cutting.

◆ Mechanical friction plate clutch is used in the spindle box of the machine tool: the speed of the motor is not changed through the control lever And stop the motor to realize the speed change, stop and reverse of the main shaft, and the main axle box is forced to be lubricated.

◆ Type B is 82mm, and type C is 105mm spindle diameter.

◆ High rigid mechanical tool rest, with high reliability and high repeated positioning accuracy.

◆ The slide box of the machine tool is equipped with a fast moving device and a safety release mechanism for the big hand wheel of the slide box. It has the interlock protection function of light screw and lead screw to ensure the normal and trouble free operation of the feeding system.

◆ The type of thread can be changed by changing the handle position of the feed box of the machine tool.

◆ The slide box of the machine tool is equipped with fast moving device and overload safety protection device; Vertical and horizontal cross operation Longitudinal handle, opening and closing nut handle.

◆ Various safety and protection accessories are available for users.

Standard configuration: large lead screw protection, foot brake, belt cover, electrical cabinet door opening and power off and other functional accessories.

Special order: tool holder protection, chuck protection, longitudinal stop device, etc.

▌Parameters

Specification Unit CDS6140B CDS6240B CDS6150B CDS250B CDS6156B CDS6256B CDS6166B CDS6266B Max.swing over bed mm Φ400 Φ500 Φ560 Φ660 Max.swing over cross slide mm Φ230 Φ290 Φ350 Φ440 Max.swing over in gap mm - Φ700 - Φ760 - Φ800 - Φ870 Gap length mm - 280 - 280 - 280 - 280 Max workpiece length mm 750/1000/1500/2000/3000/ Width over bedways mm 394 Spindle nose D8 Spindle bore mm Φ82 Chuck size mm Φ250 Φ315 Taper of spindle bore 90mm/1:20 Max. Spindle torque Nm 1100 Spindle speed ranges rpm 26-2000(16 speeds) Spindle centre height mm 220 250 280 325 Spindle motor power KW 7.5(10HP) Tailstock quill diameter mm Φ75 Tailstock quill travel mm 150 Tailstock quill taper No 5 MT Longitudinal feed 0.044-1.48mm/rpm(45kinds) Cross feed 0.022-0.74mm/rpm(45kinds) Metric Pitch mm 0.5-80(73kinds) Modular Pitch MOD 0.5-40(45kinds) Imperial Pitch TPI 7/16-80(47kinds) Diametrical Pitch DP 7/8-160(47kinds) Max.tool shank size mm 25*25 Travel of top slide mm 150 Machine overall dimensions mm 2680*1223*1265 2680*1223*1295 2680*1223*1325 2680*1223*1370 Machine weight kg 2070/2120/2370/2570/3070 2120/2170/2420/2620/3120 2180/2270/2480/2680/3180 2400/2500/2700/2900/3400

Standard configurations·3-Jaw chuck ·Lead screw cover ·Center used on the tailstock ·4-way tool post ·Foot brake ·Atandard toolkit ·φ30~φ200mm Steady rest (1500mm Available) ·φ20~φ80mm Follower rest (≥1500mm Available)

Optional configurations

·4-Jaw chuck ·American type quick-change tool post ·Chuck guard ·German type quick-change tool post ·Tool post guard ·ltaly type quick-change tool post ·Rear splash guard ·Live center ·Face plate ·Thread dial ·Drive plate ·Taper-turning attachment ·DRO ·Vertical hard stop ·Leveling pad ·Anchor bolt ·Spindle center and center sleeve ·Steady rest\Follower rest(≤1000mm Available)

Previous

Next

Online Message

Awarded as quality stable & reliable brand for continuously 11 years by clients both domes-tic and overseas

Contact Information

E-mail:info@dlrbmachinery.com

E-mail:info@dlrbmachinery.com

TEL:+86-15998569832

TEL:+86-15998569832

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

Copyright © 2022 Copyright © 2022 RAINBOW MACHINERY 辽ICP备2022001030号 Powered by:www.300.cn