PRODUCTS

- Details

-

- Commodity name: ZLS-Di

- Commodity ID: ZLS-Di

▌Introduction

rotary screw air compressor

PM VSD screw air compressor

air compressor

Compressor▌Product introduction

When you only need a pressure of 0.3~0.5MPa, if you use a conventional 0.7MPa machine to achieve this by means of pressure reduction and other means, the performance and electricity cost of the machine will be virtually wasted. With a permanent magnet low pressure large displacement screw machine, you can achieve more reliable performance and more amazing power saving effect than conventional machines under the same gas consumption. If you purchase a 0.7MPa machine, but the actual operating pressure is 0.3MPa, its working process is usually as follows: the screw host first compresses the air from 0.1MPa to 0.7MPa, and then reduces the pressure to 0.3MPa for use through pressure reducing valves and other means. In short, you need to use a pressure of 0.3MPa, but you are actually suffering from a power consumption of 0.7MPa, which is an invisible waste of energy!

▌Product detail

Unique design of low pressure and large displacement

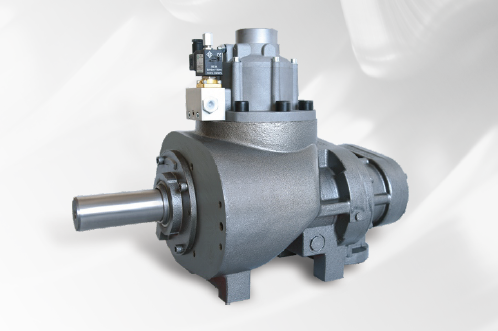

The permanent magnet oil cooling body drive technology created by Jaguar Fachuang is adopted, which is 8% more efficient than the conventional motor drive mode, and the protection level is up to IP65; The cooling fan adopts frequency conversion control, which can save 3% energy consumption while reducing noise; Permanent magnet IPM motor adopts 8 extremely high speed motors, and the energy saving efficiency is 10% higher than that of asynchronous motor.

The design scheme of large rotor, large bearing and low speed is used to ensure more stable performance; Low pressure special accessories are used for inlet valve, oil-gas separation core and minimum pressure valve to significantly improve the overall performance.

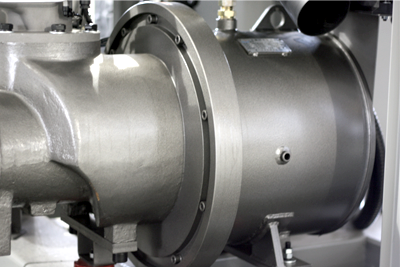

Low speed permanent magnet variable frequency screw head

Third generation asymmetric screw rotor profile and heavy load bearing selection with independent patents; Low speed and low wear greatly improve reliability;

The professional high efficiency screw head creates super large exhaust volume and ultra-low use cost. Ultra low speed, as low as 1500 RPM.▌Parameters

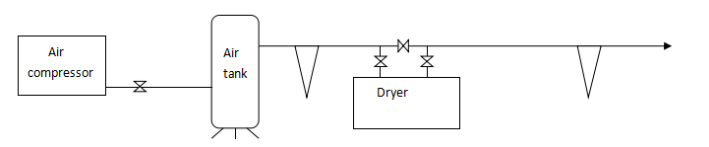

Model Mpa Exhaust volume/exhaust pressure Power Noise Exhaust port pipe diameter Weight Size m³/min kw/HP dB(A) inch KG (*W*Hmm) ZLS-30Di 0.2 2.88-7.2 22/30 64±2 1-1/2'' 500 1400*1000*1400 0.25 2.7-6.9 0.3 2.6-6.6 0.35 2.4-6 0.4 2.28-5.7 480 1250*900*1300 0.45 2.21-5 0.5 2.0-4.7 ZLS-40Di 0.2 3.7-11.3 30/40 65±2 1-1/2'' 650 1550*1130*1370 0.25 3.48-10.1 0.3 3.2-7.8 0.35 3.1-7.6 0.4 2.9-6.9 620 1400*920*1350 0.45 2.72-6.7 0.5 2.6-6.5 ZLS-50Di 0.2 5.6-14 37/50 65±2 2'' 1000 1750*1300*1600 0.25 4.88-12.2 0.3 4.27-11.8 0.35 4.4-11 0.4 4.04-10.1 1-1/2'' 780 1600*1100*1450 0.45 3.72-9.3 0.5 3.52-8.8 ZLS-60Di 0.2 6.44-16.1 45/60 66±2 2'' 1360 1750*1300*1600 0.25 6.08-15.2 0.3 5.8-14.5 0.35 5.4-13.5 0.4 4.6-11.5 980 1700*1110*1480 0.45 4.32-10.8 0.5 4.08-10.2 ZLS-75Di 0.2 8.4-21 55/75 66±3 DN80 1580 2300*1700*2050 0.25 8.08-19.3 0.3 7.44-18.2 0.35 6.88-16 0.4 6.32-15.8 2'' 1600 1750*1200*1450 0.45 5.96-14.9 0.5 5.68-14.2 ZLS-100Di 0.2 11.2-28 75/100 67±2 DN80 2140 2800*1800*2150 0.25 9.96-25.3 0.3 9.32-23.3 0.35 8.84-22.1 0.4 8.4-21 DN65 1820 2400*1750*1900 0.45 7.76-19.4 0.5 7.44-18.6 ZLS-125Di 0.2 13.84-36.5 90/125 68±2 DN150 3190 3250*2000*2050 0.25 12.88-34.8 0.3 11.6-29 0.35 11.04-27.6 0.4 10.2-25.5 DN80 2210 2900*1900*2050 0.45 9.6-24 0.5 9.12-22.8 ZLS-150Di 0.2 18-45 110/150 70±2 DN150 4900 3600*2000*2250 0.25 15.52-38.8 0.3 14.72-36.8 0.35 13.92-34.8 0.4 12.4-31 DN80 3090 3000*2000*2050 0.45 10.8-27 0.5 10.2-25.5 ZLS-175Di 0.2 19.2-51.8 132/175 70±2 DN200 6100 3600*2000*2250 0.25 18-45 0.3 16.88-42.2 0.35 16.08-40.2 0.4 15.28-36.86 DN100 4850 3200*2000*2100 0.45 14-32 0.5 13.52-31.44 ZLS-200Di 0.2 24-60 160/200 70±2 DN200 7400 3600*2000*2250 0.25 22.4-56 0.3 19.6-50.5 0.35 19.36-48.4 0.4 18.4-43.86 DN100 6050 3500*2400*2200 0.45 17.2-42 0.5 16.04-39.983 ZLS-250Di 0.2 28-70 185/250 72±2 DN200 7700 4000*2300*2250 0.25 26-67.6 0.3 23.6-62.9 0.35 22.8-59 0.4 20-50 DN125 7000 3600*2000*2250 0.45 19.2-48 0.5 18.4-46 ZLS-275Di 0.2 30.8-77 200/275 74±2 DN200 7400 4000*2300*2250 0.25 29-72.5 0.3 27.04-67.6 0.35 25.16-62.9 0.4 22.64-56.6 7200 3600*2000*2250 0.45 20.8-52 0.5 19.6-49 ZLS-300Di 0.2 32.8-82 220/300 76±2 DN200 8400 4000*2300*2250 0.25 30.8-77 0.3 28.92-72.3 0.35 27-67.5 0.4 25.12-62.8 DN150 7400 4000*2300*2250 0.45 22.4-56 0.5 21.2-53 ZLS-350Di 0.2 34.4-86 250/350 78±2 DN200 8600 4500*2800*-2400 0.25 32.4-81 0.3 30.6-76.5 0.35 28.8-72 0.4 27.6-69 DN200 7600 0.45 24.4-61 0.5 23.6-59 ZLS-375Di 0.2 36.8-110.2 280/375 78±2 DN200 9000 4500*2800*2400 0.25 34.8-102.5 0.3 32.8-95.5 0.35 30.8-85.5 0.4 28.6-79.5 DN200 7800 0.45 26.8-67 0.5 25.6-64 ▌Configurattion diagram

▌Manufacturing technique

1.High Precision CBN Grinding Machine

2.Imported DMG MORI CNC Horizontal machining Center

3.Imported German Zeiss CMM Measuring Center

4.Imported Italian Salvagnini Dynamic Laser Cutting Machine

High Precision Equipment for manufacturing High Precision Screw Rotors EAMI uses professional high-precision manufacturing equipment, to ensure high standard design requirements, The screw screw rotor is grinded with high precision, and the machining precision reaches 0.005mm. The surface roughness reaches Ra0.1-0.2um.▌Application

▌Certifications

▌Packaging & Shipping

▌FAQ

Online Message

Awarded as quality stable & reliable brand for continuously 11 years by clients both domes-tic and overseas

Contact Information

E-mail:info@dlrbmachinery.com

E-mail:info@dlrbmachinery.com

TEL:+86-15998569832

TEL:+86-15998569832

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

Copyright © 2022 Copyright © 2022 RAINBOW MACHINERY 辽ICP备2022001030号 Powered by:www.300.cn