PRODUCTS

- Details

-

- Commodity name: ZLS-2Di

- Commodity ID: ZLS-2Di

▌Introduction

Jaguar permanent magnet screw with low pressure and large displacement has many advantages, such as large gas production, energy saving and low noise. It is now widely used in textile chemical fiber, packaging, glass, cement, chemical and hardware products, saving more than 50% of the electricity cost compared with conventional models. Long term use will save a huge amount of energy expenditure for enterprises and contribute to social energy conservation and emission reduction.

Power: 30HP~475HP

rotary screw air compressor

PM VSD screw air compressor

screw air compressor

air compressor

Compressor

Under what circumstances do you need to use permanent magnet with low voltage and large displacement?

When you only need a pressure of 0.3~0.5MPa, if you use a conventional 0.7MPa machine to achieve this by means of pressure reduction and other means, the performance and electricity cost of the machine will be virtually wasted. With a permanent magnet low pressure large displacement screw machine, you can achieve more reliable performance and more amazing power saving effect than conventional machines under the same gas consumption. If you purchase a 0.7MPa machine, but the actual operating pressure is 0.3MPa, its working process is usually as follows: the screw host first compresses the air from 0.1MPa to 0.7MPa, and then reduces the pressure to 0.3MPa for use through pressure reducing valves and other means. In short, you need to use a pressure of 0.3MPa, but you are actually suffering from a power consumption of 0.7MPa, which is an invisible waste of energy!

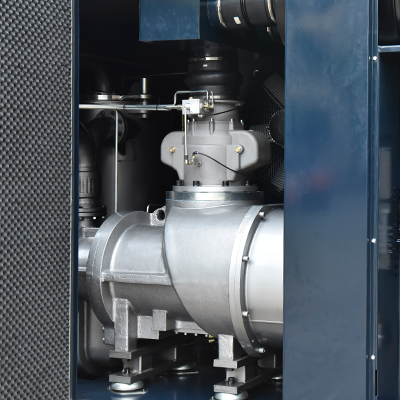

▌Product details

Advantages of dual motor and dual host transmission

The two-stage compression structure that replaces the old gear drive is directly driven by a full motor. The two air compressors are independent and can work together. After sales maintenance can facilitate the maintenance and repair of the handpiece group, without the need to disassemble it at the same time. It can make your after-sales maintenance plan more efficient, and the maintenance cost is greatly reduced.

1.Double motors are driven independently, the compression ratio of each stage is reduced compared with that of single stage compression, the leakage backflow between rotors is greatly reduced, and the gas production is increased;

2. It is easy to maintain, the machine head is easy to maintain, it can operate efficiently for a long time, the machine head is simple to manufacture, and the machine head failure rate is reduced;

3. The intermediate pressure shall be adjusted flexibly;

4. Change the host at will to achieve different pressures and higher energy efficiency.

Efficient and stable cooling system

A special cooling spray design is adopted at the end of the first stage bearing pedestal for the first and second stage heads to better cool the first and second stages, making the second stage compression of the air compressor closer to is othermal compression.

The industry's original water cooling system is used to ensure the stable control of the heat generation of the permanent magnet motor. The self circulating water circuit does not need to introduce external water sources, so you do not need to worry about the high temperature problem of your air compressor motor.

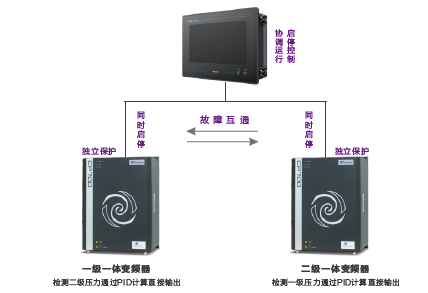

Using dedicated dual drivers

After the ZLS-2Di two-stage compression low press is started, the display and control integrated machine sends the start command. Through the high-speed communication protocol, the rapid response between the two stages can be ensured and the two integrated frequency converters can be started at the same time. After the frequency converter is started, the internal control system of the frequency converter independently controls the pressure transmitters at all levels, which are directly connected to the integrated frequency converter. The speed of pressure reading and PID response is faster, ensuring fast and constant pressure. The coordinated work starts and stops at the same time. When any air compressor stops or fails, the other one will stop immediately. Even if the communication line is broken, the integrated air compressor can also be protected independently. According to the value monitored by the sensor, it can be protected and shut down.

The new frequency converter is adopted, and the special control algorithm enables the two frequency converters to coordinate with each other, control the screw air compressor orderly and stably, and provide you with compressed air of constant pressure.

▌Parameters

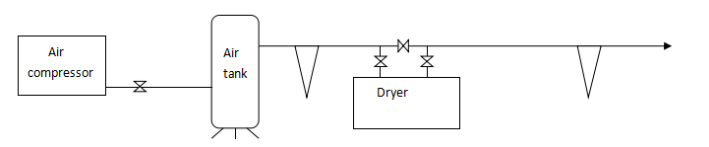

Model Mpa Exhaust volume/exhaust pressure Power Noise Exhaust port pipe diameter Weight Size m³/min kw/HP dB(A) inch KG (*W*Hmm) ZLS30-2Di 0.45 7.1 22/30 63±2 1-1/2'' 1000 1660*1150*1480 0.5 6.9 0.55 6.3 0.6 6 ZLS40-2Di 0.45 9 30/40 64±2 1-1/2'' 1240 1660*1150*1480 0.5 8.8 0.55 8.3 0.6 8.1 ZLS50-2Di 0.45 10.3 37/50 64±2 1-1/2'' 1460 1750*1280*1600 0.5 9.9 0.55 9.3 0.6 9.1 ZLS60-2Di 0.45 13.2 45/60 65±2 2'' 1680 1750*1280*1600 0.5 12.7 0.55 12.1 0.6 11.8 ZLS75-2Di 0.45 16.2 55/75 70±3 2'' 2150 1800*1300*1700 0.5 15.9 0.55 15.5 0.6 15.2 ZLS100-2Di 0.45 20.8 75/100 71±3 2'' 2800 2800*1650*1800 0.5 19.4 0.55 19 0.6 18.7 ZLS125-2Di 0.45 25.7 90/125 73±3 DN80 3300 2800*1650*1800 0.5 24.5 0.55 23.6 0.6 22 ZLS150-2Di 0.45 30 110/150 74±3 DN100 3960 3200*1800*2050 0.5 29.3 0.55 28.2 0.6 26.9 ZLS175-2Di 0.45 38.4 132/175 79±3 DN100 5200 3800*2000*2050 0.5 36.6 0.55 35 0.6 33.4 ZLS200-2Di 0.45 44.2 160/200 79±3 DN100 6500 3800*2000*2050 0.5 43.3 0.55 42.1 0.6 39.6 ZLS250-2Di 0.45 50 185/250 79±3 DN100 6800 3300*2000*2100 0.5 48 0.55 46 0.6 44.5 ZLS275-2Di 0.45 53.5 200/275 79±3 DN125 7000 4200*2300*2200 0.5 52 0.55 48 0.6 61.2 ZLS300-2Di 0.45 61.2 220/300 80±3 DN125 7600 4200*2300*2200 0.5 57 0.55 55.5 0.6 52.4 ZLS350-2Di 0.45 67.6 250/350 80±3 DN150 8200 4500*2500*-2350 0.5 64.5 0.55 61 0.6 58.2 ZLS375-2Di 0.45 75.5 280/375 82±3 DN150 8800 4500*2500*2350 0.5 72.3 0.55 68.4 0.6 65.1 ZLS420-2Di 0.45 85 315/420 82±3 DN200 9600 4500*2800*2350 0.5 81.3 0.55 77 0.6 73.1 ZLS475-2Di 0.45 95.7 365/475 86±3 DN200 10700 4500*2800*2350 0.5 91.6 0.55 86.8 0.6 82.4 ▌Configurattion diagram

▌Manufacturing technique

1.High Precision CBN Grinding Machine

2.Imported DMG MORI CNC Horizontal machining Center

3.Imported German Zeiss CMM Measuring Center

4.Imported Italian Salvagnini Dynamic Laser Cutting Machine

High Precision Equipment for manufacturing High Precision Screw Rotors EAMI uses professional high-precision manufacturing equipment, to ensure high standard design requirements, The screw screw rotor is grinded with high precision, and the machining precision reaches 0.005mm. The surface roughness reaches Ra0.1-0.2um.▌Application

▌Certifications

▌Packaging & Shipping

▌FAQ

Online Message

Awarded as quality stable & reliable brand for continuously 11 years by clients both domes-tic and overseas

Contact Information

E-mail:info@dlrbmachinery.com

E-mail:info@dlrbmachinery.com

TEL:+86-15998569832

TEL:+86-15998569832

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

Copyright © 2022 Copyright © 2022 RAINBOW MACHINERY 辽ICP备2022001030号 Powered by:www.300.cn