PRODUCTS

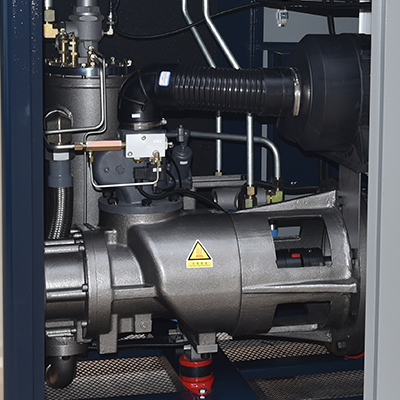

ZLS Screw Air Compressor With Direct Drive

Reference price

Stock

隐藏域元素占位

- Details

-

- Commodity name: ZLS Screw Air Compressor With Direct Drive

- Commodity ID: ZLS Screw Air Compressor With

▌Introduction

Jaguar screw air compressor chooses Jaguar new generation of micro-oil lubricating screw air compressor technology, with the advantages of reliable running performance, less wearing parts, low vibration, low noise and high efficiency while under high running efficiency. In the meanwhile the Jaguar intelligent control system helps to save more electricity and cost.

Power: 45KW~250KWrotary screw air compressor

PM VSD screw air compressor

screw air compressor

air compressor

Compressor

The coaxial transmission compressor chooses JAGUAR third generation screw profile lowering the failure rate and prolonging the service life.

▌Advantages of direct drive screw type series

The screw host is designed with the third generation of JAGUAR screw model line. According to the idea of large rotor, large bearing and low speed, all models are designed with a pair of continuous connection. Low speed reduces the failure rate and ensures a long service life of the host.

The direct transmission mode is adopted, with high transmission efficiency, reliable imported couplings, easy installation, even stress on the elastomer, and long service life.▌Product details

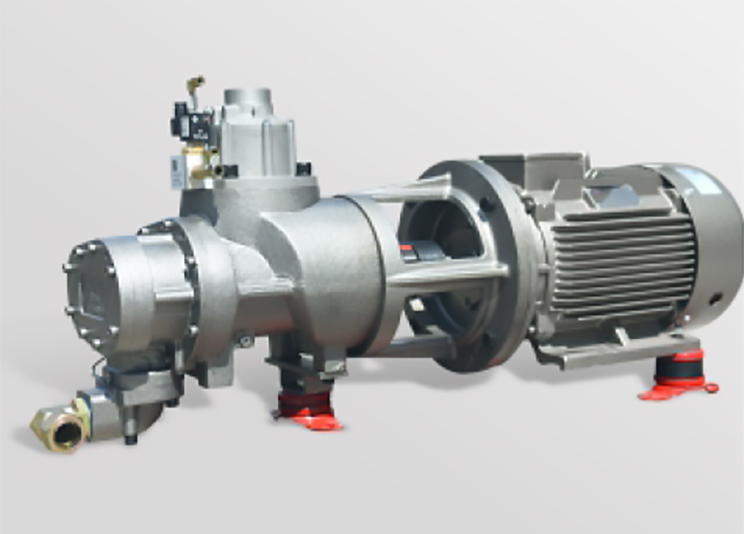

1.JAGUAR High precision air-end

Due to the development of JAGUAR profiles and strengthening of steel bearings, our products have been repeatedly tested many times to provide customers with large discharge and the machine’s life is greatly increased.

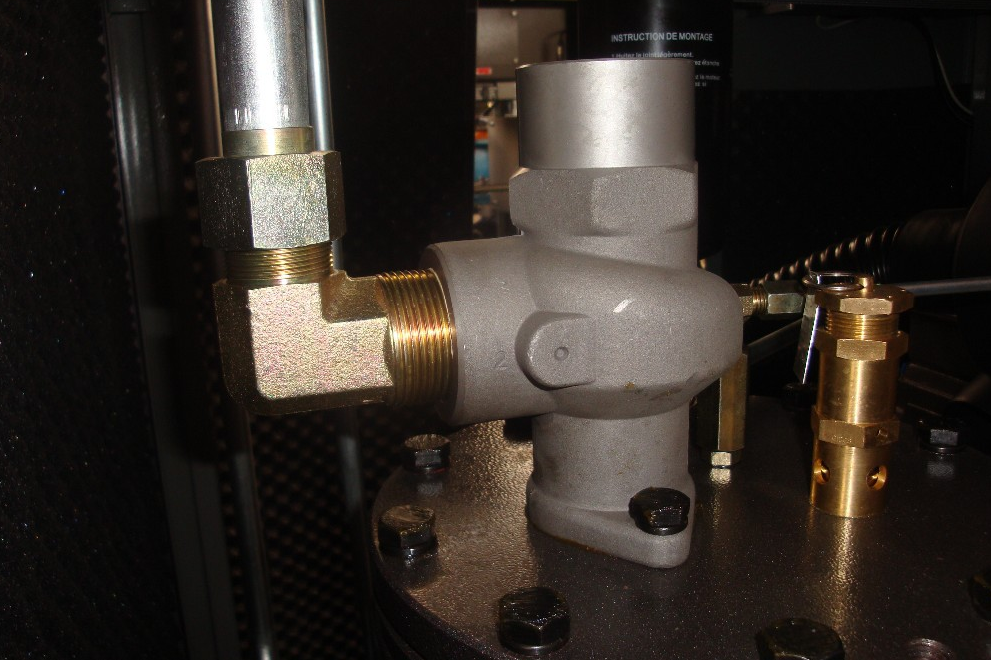

2.JAGUAR Pressure valve

We will configure the pressure valve based on customers’ demands and ensure that there’s no problem in the use process, according to the real pressure needs of customers to satisfy customers.

3.JAGUAR Intake valve

Using unique design for our large aperture is able to reduce pressure abrasion, thus machine can be used for a long time.

4.JAGUAR air filter

We use imported material filters to effectively filter 99% of impurities, simultaneously reduce the use cost for customers.

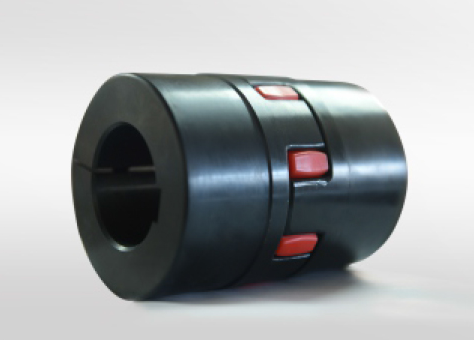

5.JAGUAR coupling

Why the JAGUAR compressor can generate few vibration, because the air-end and asynchronous motor use special gaskets, which can effectively reduce transmission vibration.

6.JAGUAR asynchronous motor

IP54 wind cooling system has substantially reduced the electric current, in addition to stabilizing the electric motor’s temperature.

▌Coaxial transmission

1.The coaxial transmission reduces transmission loss, prolongs motor service life, increases transmission efficiency and reduces footprint.

2.Variable frequency controller: variable frequency is adopted to provide stable pressure and gas consumption state suitable for customers. Professional heat dissipation design can operate at 50 ℃ ambient temperature, automatically adjust the output rating under temperature rise conditions, and maintain the continuous and efficient operation of the inverter.▌Parameters

Model Mpa Exhaust volume/exhaust pressure Power Noise Exhaust port pipe diameter Weight Size m³/min kw/HP dB(A) inch KG (*W*Hmm) ZLS60 0.7 8 45/60 73 1-1/2'' 920 1550*1050*1460 0.8 7.5 1 7 1.25 5.8 ZLS75 0.7 10.5 55/75 73 2'' 1160 1600*1150*1580 0.8 9.8 1 8.6 1.25 7.8 ZLS100 0.7 13.9 75/100 75 2'' 1550 1910*1150*1580

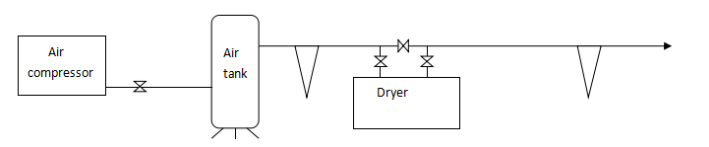

1700*1200*15800.8 12.8 1 11.8 1.25 10.5 ZLS125 0.7 16 90/125 75 2'' 1850 2150*1350*1700 0.8 15.5 1 13.9 1.25 12.3 ZLS150 0.7 20.5 110/150 77 DN65 2450 2500*1650*1920 0.8 19 1 17.4 1.25 16.3 ZLS175 0.7 24.1 132/175 77 3'' 2700 3000*1800*2050 0.8 22.9 1 20.1 1.25 18.7 ZLS200 0.7 28.3 160/200 79 DN80 2890 3000*1800*2050 0.8 27 1 24.3 1.25 21.2 ZLS250 0.7 32.5 185/250 79 DN100 3000 3000*2000*2050 0.8 30 1 26.7 1.25 24.2 ZLS300 0.7 38.5 220/300 79 DN100 4400 3950*2300*2200 0.8 35.8 1 29.8 1.25 27.6 ZLS350 0.7 43.8 250/350 80 4'' 4610 3950*2300*2200 0.8 41.4 1 35.5 1.25 33.2 ZLS400 0.7 52 300/400 80 5'' 6000 4000*2300*2200 0.8 48 1 40.8 1.25 38.2 ▌Configurattion diagram

▌Manufacturing technique

1.High Precision CBN Grinding Machine

2.Imported DMG MORI CNC Horizontal machining Center

3.Imported German Zeiss CMM Measuring Center

4.Imported Italian Salvagnini Dynamic Laser Cutting Machine

High Precision Equipment for manufacturing High Precision Screw Rotors EAMI uses professional high-precision manufacturing equipment, to ensure high standard design requirements, The screw screw rotor is grinded with high precision, and the machining precision reaches 0.005mm. The surface roughness reaches Ra0.1-0.2um.▌Application

▌Certifications

▌Packaging & Shipping

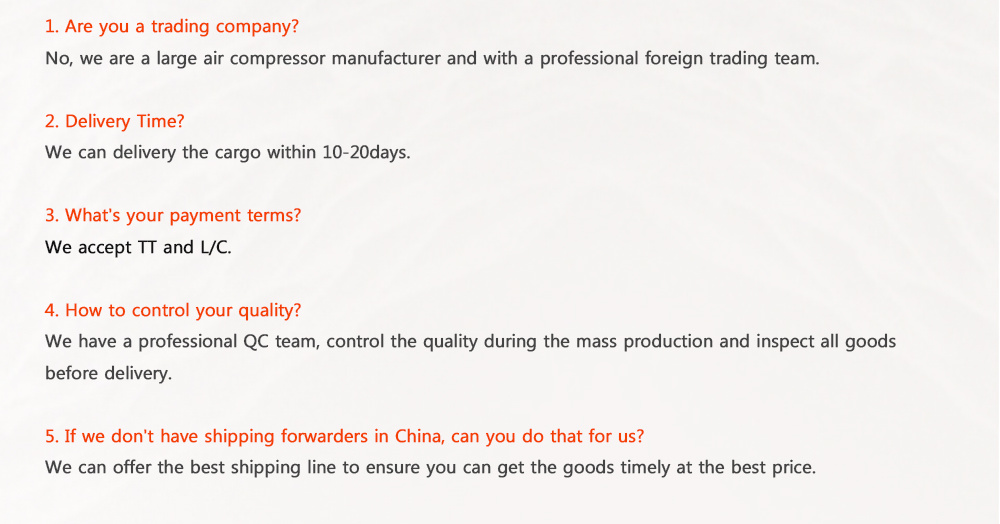

▌FAQ

Online Message

Awarded as quality stable & reliable brand for continuously 11 years by clients both domes-tic and overseas

Contact Information

E-mail:info@dlrbmachinery.com

E-mail:info@dlrbmachinery.com

TEL:+86-15998569832

TEL:+86-15998569832

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

Copyright © 2022 Copyright © 2022 RAINBOW MACHINERY 辽ICP备2022001030号 Powered by:www.300.cn