PRODUCTS

EA-10 Jaguar Star Frequency Screw Machine

Reference price

Stock

隐藏域元素占位

- Details

-

- Commodity name: EA-10 Jaguar Star Frequency Screw Machine

- Commodity ID: EA-10 Jaguar Star Frequency Scre

▌Introduction

Jaguar Sky star series adopts the third generation asymmetric screw rotor profile independently developed, high-efficiency screw heads optimized through repeated experiments in national key laboratories, and carefully matched heavy-duty bearings. Users can provide excess air displacement and extra long service life. The effect of energy conservation and consumption reduction is significant, helping enterprises achieve cost reduction and efficiency increase.

▌Description

The bearing free suspension vertical coaxial structure is adopted to ensure the straight shaft transmission and completely eliminate the transmission loss caused by bearings and couplings. The efficiency of belt conveyor and direct coupled transmission in the same power section is increased by 2%~5% compared with that of the same power section, and the energy-saving effect is significant under long-term operation.

The motor adopts a bearingless cantilever structure. Jaguar's unique design and integrated motor structure reduce the number of transmission parts, greatly reduce the volume of the screw machine, and improve the efficiency of the screw machine.

▌Advantages

Specially designed inlet valve group: the specially designed large caliber inlet valve group is used to reduce the pressure loss. The solenoid valve precisely controls the loading/unloading and regulates the output gas volume of the compressor to ensure the stability of the system pressure. Efficient oil-gas separation barrel: the design of oil-gas separation barrel head is canceled, and a new flat bottom design is adopted to maximize the volume of oil-gas separation barrel, so as to make oil-gas separation more thorough and provide users with cleaner gas without oil.

Efficient and stable oil filter: stable and high-quality oil filter, using imported filter materials, can effectively filter 99% of the impurities in the oil, greatly extending the service life of the screw machine. Well designed top cooling system: Well designed cooling system, the cold air first takes away the surface temperature of each heating element, and then cools the oil/gas temperature through the forced heat exchange of the top high-efficiency cooler. The hot air is discharged at the top, which conforms to the principle of air thermodynamics, ensuring efficient cooling while reducing the noise of the unit. Advanced intelligent control system: display and control are integrated, giving consideration to control, monitoring, alarm and recording, which is convenient and fast to operate. The control button is stable, durable and feels good.

▌Parameters

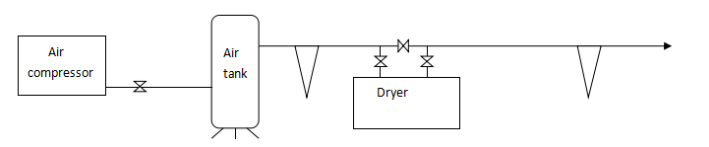

Power 7.5KW/10HP Rated power 0.8MPa Exhaust volume 1m³/min Unit noise 62±2dB(A) Motor Permanent magnet synchronization Cooling way Air-cooled Dust content ≤3μm Oil content ≤3Ppm Exhaust temperature ≤ambient temperature+10℃ Exhaust port pipe diameter 3/4” Size 750*650*900mm Weight 160kg ▌Configurattion diagram

▌Manufacturing technique

1.High Precision CBN Grinding Machine

2.Imported DMG MORI CNC Horizontal machining Center

3.Imported German Zeiss CMM Measuring Center

4.Imported Italian Salvagnini Dynamic Laser Cutting Machine

High Precision Equipment for manufacturing High Precision Screw Rotors EAMI uses professional high-precision manufacturing equipment, to ensure high standard design requirements, The screw screw rotor is grinded with high precision, and the machining precision reaches 0.005mm. The surface roughness reaches Ra0.1-0.2um.▌Application

▌Certifications

▌Packaging & Shipping

▌FAQ

Online Message

Awarded as quality stable & reliable brand for continuously 11 years by clients both domes-tic and overseas

Contact Information

E-mail:info@dlrbmachinery.com

E-mail:info@dlrbmachinery.com

TEL:+86-15998569832

TEL:+86-15998569832

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

Copyright © 2022 Copyright © 2022 RAINBOW MACHINERY 辽ICP备2022001030号 Powered by:www.300.cn