PRODUCTS

- Details

-

- Commodity name: LS Integrated Screw Air Compressor

- Commodity ID: LS Integrated Screw Air Compress

▌Introduction

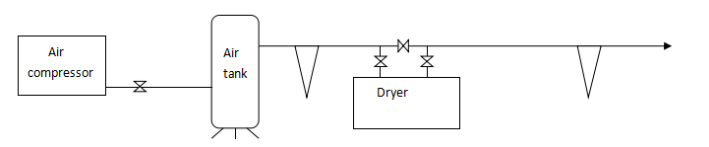

Jaguar LS series air compressor integrated air dryer, air tank and line filter, with the advantages of large air displacement, energy-saving, low noise, less footprint. The compressor with PM VSD technology can save 50% more electricity than a normal screw air compressor.

Power: 7.5 KW~22KWrotary screw air compressor

PM VSD screw air compressor

screw air compressor

air compressor

Compressor▌Advantages

1.Energy-saving:PM VSD technology makes energy-saving up to 50%

2.2.Integrated air system:compact structure, high reliability, longer service life

3.Pure compressed air: High-efficiently precision line filter ensures the supply of pure gas.

4.Integrated control system:The integrated controller is adopted, the screw compressor and air dryer are controlled by one button, which makes the operation more convenient.▌Product details

Unique design

Jaguar LS integrated screw machine series adopts integrated control system, display and control integrated machine, which can control the start and stop of screw machine and cold dryer with one key, making operation more convenient.

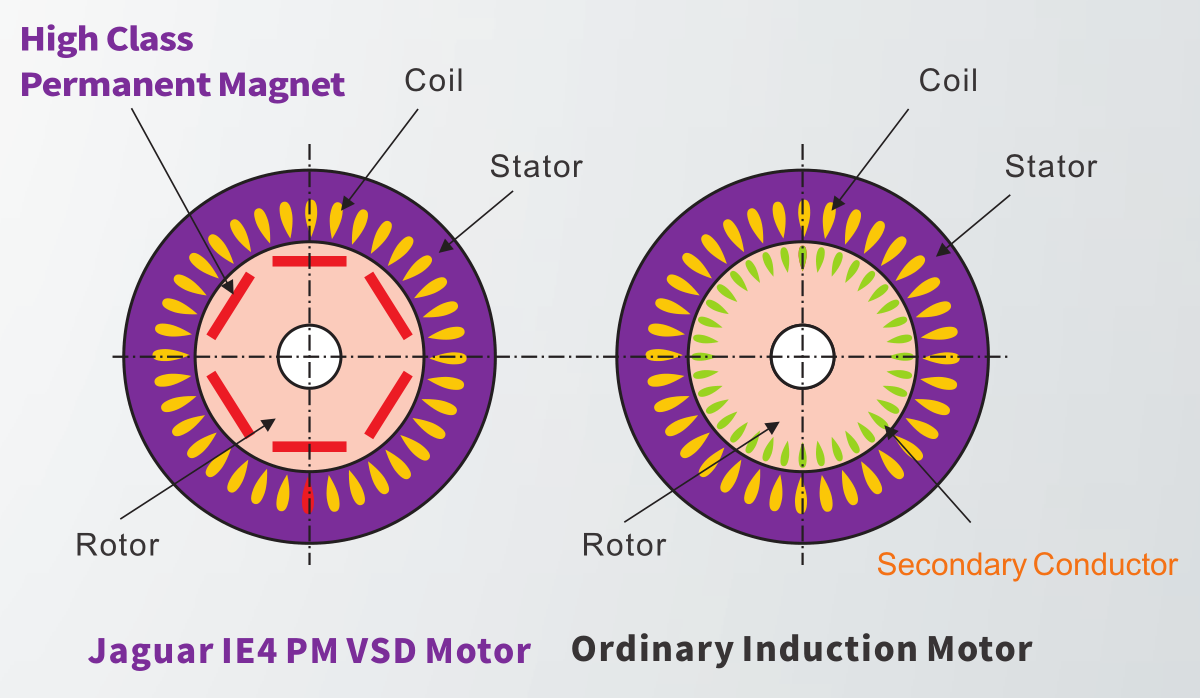

The whole series is equipped with IE4 permanent magnet variable-frequency ultra high efficiency motor. Compared with the electric excitation synchronous motor, the permanent magnet variable-frequency motor has the characteristics of ultra-high energy efficiency, compact structure, small size, light weight, etc. Jaguar's original permanent magnet liquid cooling integrated drive technology, which is 8% more efficient than the conventional motor drive mode, has a protection level of up to IP65.

Jaguar Patent Application Liquid Cooled Permanent Magnet Motor

Jaguar's unique technology development uses liquid (water type oil) to cool the permanent magnet motor housing, ensuring that the permanent magnet motor has a stable temperature and never loses excitation.

The heavy-duty bearing is adopted, and the optimal bearing configuration is selected according to the working conditions of the main engine. The bearing bearing capacity is improved, the machine head runs stably, and the service life of the whole machine is greatly increased.The advantage of IE4 permanent magnet motor

Permanent magnet VSD motor conforming to IEC 60034-30-2008.

The professional certification authority assured it.Benefits of using IE4 PM VSD motor

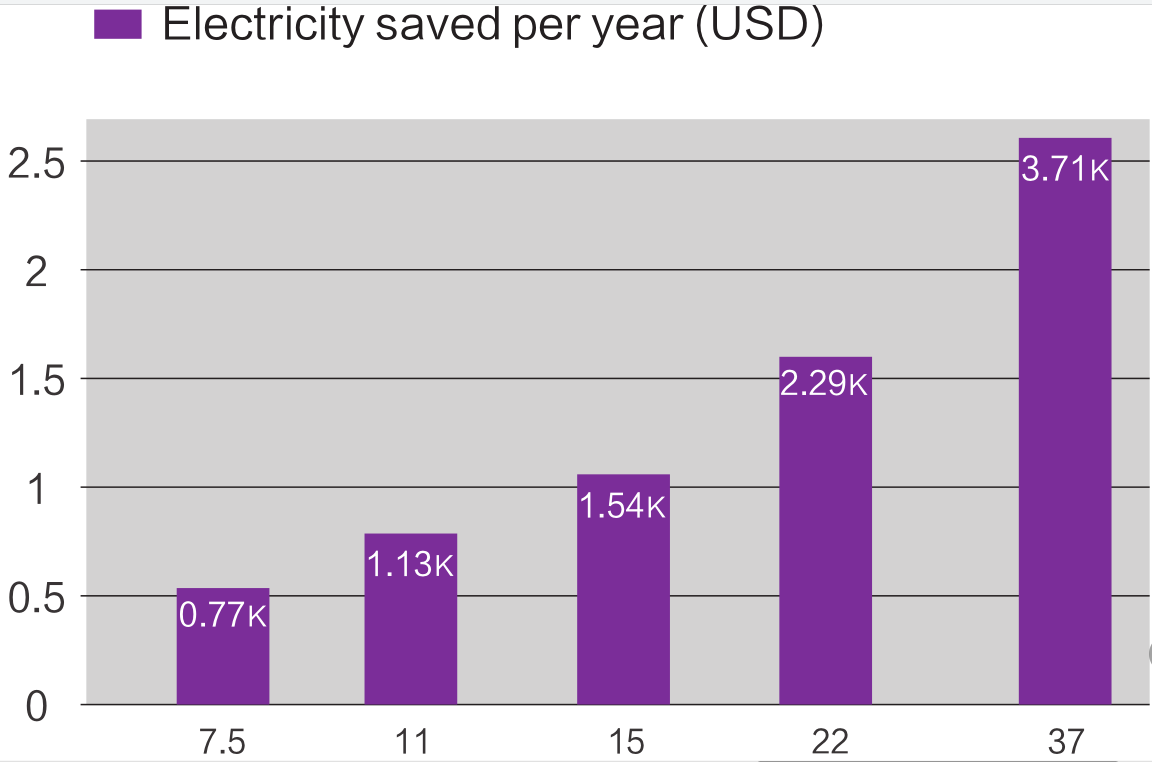

Comparing with the IE1 motor air compressor, IE4 PM VSD motor air compressor can save USD3,710 per year great benefit.

Example for same model compressor but IE1 and IE4 motor comparing, 7200 hours/year, 1KWH=USD0.14▌Parameters

Model Mpa Exhaust volume/exhaust pressure Power Gas tank Noise Weight Size m³/min kw/HP L dB(A) KG (*W*Hmm) LS10 0.8 1.1 7.5/10 260 61±2 416 1500*750*1640 1 0.95 1.25 0.85 1.5 0.75 LS15 0.8 1.7 11/15 380 61±2 490 1750*750*1700 1 1.5 1.25 1.3 1.5 1.1 LS20 0.8 2.4 15/20 380 62±2 522 1750*750*1700 1 2 1.25 1.7 1.5 1.5 LS30 0.8 3.8 22/30 600 64±2 610 1890*820*1920 1 3.1 1.25 2.5 1.5 2.3 EAS50 0.8 6.3 37/50 600 64±2 800 2000*900*1970 1 5.6 1.25 5.1 1.5 4.2 ▌Configurattion diagram

▌Manufacturing technique

1.High Precision CBN Grinding Machine

2.Imported DMG MORI CNC Horizontal machining Center

3.Imported German Zeiss CMM Measuring Center

4.Imported Italian Salvagnini Dynamic Laser Cutting Machine

High Precision Equipment for manufacturing High Precision Screw Rotors EAMI uses professional high-precision manufacturing equipment, to ensure high standard design requirements, The screw screw rotor is grinded with high precision, and the machining precision reaches 0.005mm. The surface roughness reaches Ra0.1-0.2um.▌Application

▌Certifications

▌Packaging & Shipping

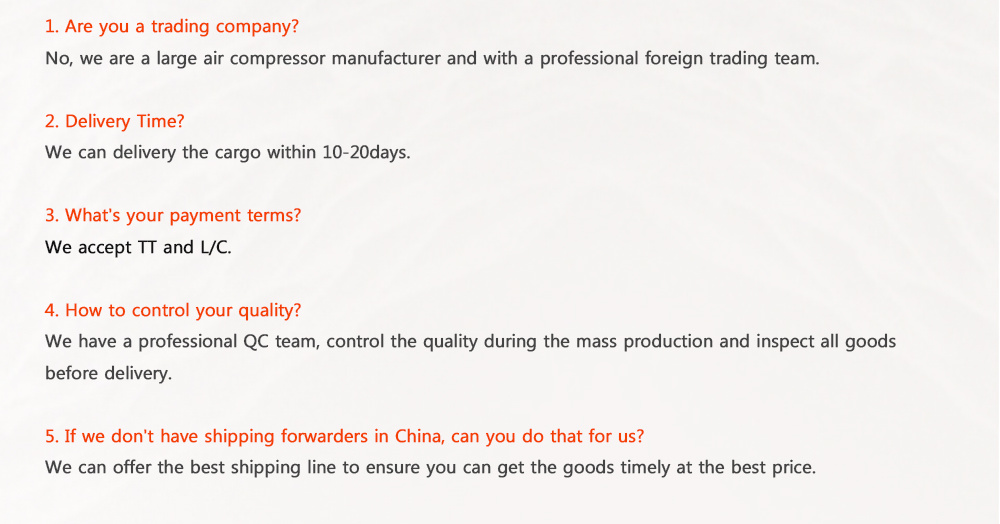

▌FAQ

Online Message

Awarded as quality stable & reliable brand for continuously 11 years by clients both domes-tic and overseas

Contact Information

E-mail:info@dlrbmachinery.com

E-mail:info@dlrbmachinery.com

TEL:+86-15998569832

TEL:+86-15998569832

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

Copyright © 2022 Copyright © 2022 RAINBOW MACHINERY 辽ICP备2022001030号 Powered by:www.300.cn