PRODUCTS

- Details

-

- Commodity name: EAS Screw Air Compressor With Belt Drive

- Commodity ID: EAS Screw Air Compressor With Be

▌Introduction

Jaguar belt drive screw air compressor uses high-precision air-end and good quality spare parts, having a higher transmission efficiency, longer service life. The compressor is widely used in equipment manufacturing, automobile, electric power, medical, textile, photovoltaic, semiconductor and other fields.

Power: 7.5 KW~55KW

rotary screw air compressor

screw air compressor

air compressor

compressor

▌Product introduction

Large discharge: The compressor chooses the new screw profile, with large discharge.

Lower energy consumption: The compressor has high volume ratio and high mechanical efficiency.

Low purchase cost: The simple and compact structure designed compressor has stable quality and reasonable cost.

Maintenance-free:The compressor has a lower maintenance cost due to within less spare parts and no wearing parts.Belt Drive Screw Air Compressor

Theory:

Electronic motor and main engine through belt transfer power.▌Advantages

1. Massive displacement: the latest rotor design, large air displacement. .

2.High energy efficiency: high volume rate, low friction, high mechanical efficiency.

3.Low cost: simple structure, compact structure, mature and reliable product, and reasonable price.

4.Less maintenance: The structure and components we designed are simple, therefore the option is easier, which can reduce maintenance costs.

5.Quick change: the change of work pressure-demand only needs simple replacement of belt pulley, convenient and fast.▌Product details

Belt driven compressor

Jaguar's third generation asymmetric screw rotor profile and heavy load bearing selection are adopted, and the high-efficiency screw head is optimized through repeated experiments to provide users with super large air displacement and extend the service life.

High efficiency asynchronous motor: the whole machine adopts high efficiency asynchronous motor with small vibration. IP54 air cooling system can greatly reduce the motor current and stably control the motor temperature rise.Belt: Imported German belt make sure transmission efficiency higher and longer service life.

Air/Oil Filter: Imported materials, effectively protect the air compressor, significantly prolong the life of air compressor.

Electrical Control: Internationally renowned components reliable, safe, and easy to operate.

▌Parameters

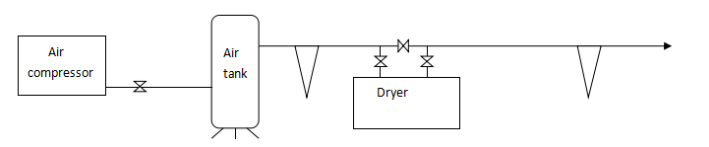

Model Mpa Exhaust volume/exhaust pressure Power Lubricant quantity Noise Exhaust port pipe diameter Weight Size m³/min kw/HP L dB(A) inch KG (*W*Hmm) EAS10 0.8 1.2 7.5/10 10 66±2 1'' 300 950*690*1190 1 1 1.25 0.8 1.5 0.6 EAS15 0.8 1.6 11/15 10 66±2 1'' 390 1050*850*1160 1 1.3 1.25 1 1.5 0.8 EAS20 0.8 2.3 15/20 10 68±2 1'' 410 1050*850*1160 1 2 1.25 1.7 1.5 1.3 EAS30 0.8 3.4 22/30 11 70±2 1-1/4'' 500 1180*800*1200 1 3.1 1.25 2.7 1.5 2 EAS40 0.8 5 30/40 13 70±2 1-1/4'' 590 1180*950*1310 1 4.3 1.25 3.8 1.5 2.8 EAS50 0.8 6.1 37/50 18 72±2 1-1/2'' 700 1350*990*1340 1 5.5 1.25 4.9 1.5 3.6 ▌Configurattion diagram

▌Manufacturing technique

1.High Precision CBN Grinding Machine

2.Imported DMG MORI CNC Horizontal machining Center

3.Imported German Zeiss CMM Measuring Center

4.Imported Italian Salvagnini Dynamic Laser Cutting Machine

High Precision Equipment for manufacturing High Precision Screw Rotors EAMI uses professional high-precision manufacturing equipment, to ensure high standard design requirements, The screw screw rotor is grinded with high precision, and the machining precision reaches 0.005mm. The surface roughness reaches Ra0.1-0.2um.▌Application

▌Certifications

▌Packaging & Shipping

▌FAQ

Online Message

Awarded as quality stable & reliable brand for continuously 11 years by clients both domes-tic and overseas

Contact Information

E-mail:info@dlrbmachinery.com

E-mail:info@dlrbmachinery.com

TEL:+86-15998569832

TEL:+86-15998569832

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

ADD:No.6-2, HuaiHe ZhongLu, Dalian Economic and Technological Development Zone, Liaoning Province

Copyright © 2022 Copyright © 2022 RAINBOW MACHINERY 辽ICP备2022001030号 Powered by:www.300.cn